2024

Cone completed a rooftop solar power project at Cone Denim’s mill in Jiaxing, China. The solar rooftop generates 9 megawatt-hours annually for the plant.

2023

Cone Denim returns to its roots at Revolution Mill with its Greensboro, N.C., division office relocating to the former flannel mill.

Cone renews RCS certification to include a fiber supplier, establishing a supply chain for certified recycled cotton in Mexico.

Also this year, Cone Denim installs G2 Jeanologia Ozone finishing technology in Jiaxing and Yecapixtla to further enhance water-saving initiatives.

2020

Cone partners with Oritain™ to become the first denim mill to offer forensic verification of cotton traceability.

Also this year, Cone Denim installs G2 Jeanologia Ozone finishing technology in Jiaxing and Yecapixtla to further enhance water-saving initiatives.

2017-19

Cone Denim partners with Westex® by Milliken® to produce flame-resistant denim. Also this year, Cone Denim returns to its roots with the unveiling of Natural Indigo Selvage Denim, produced exclusively at its historic White Oak mill in celebration of White Oak’s 110-year anniversary.

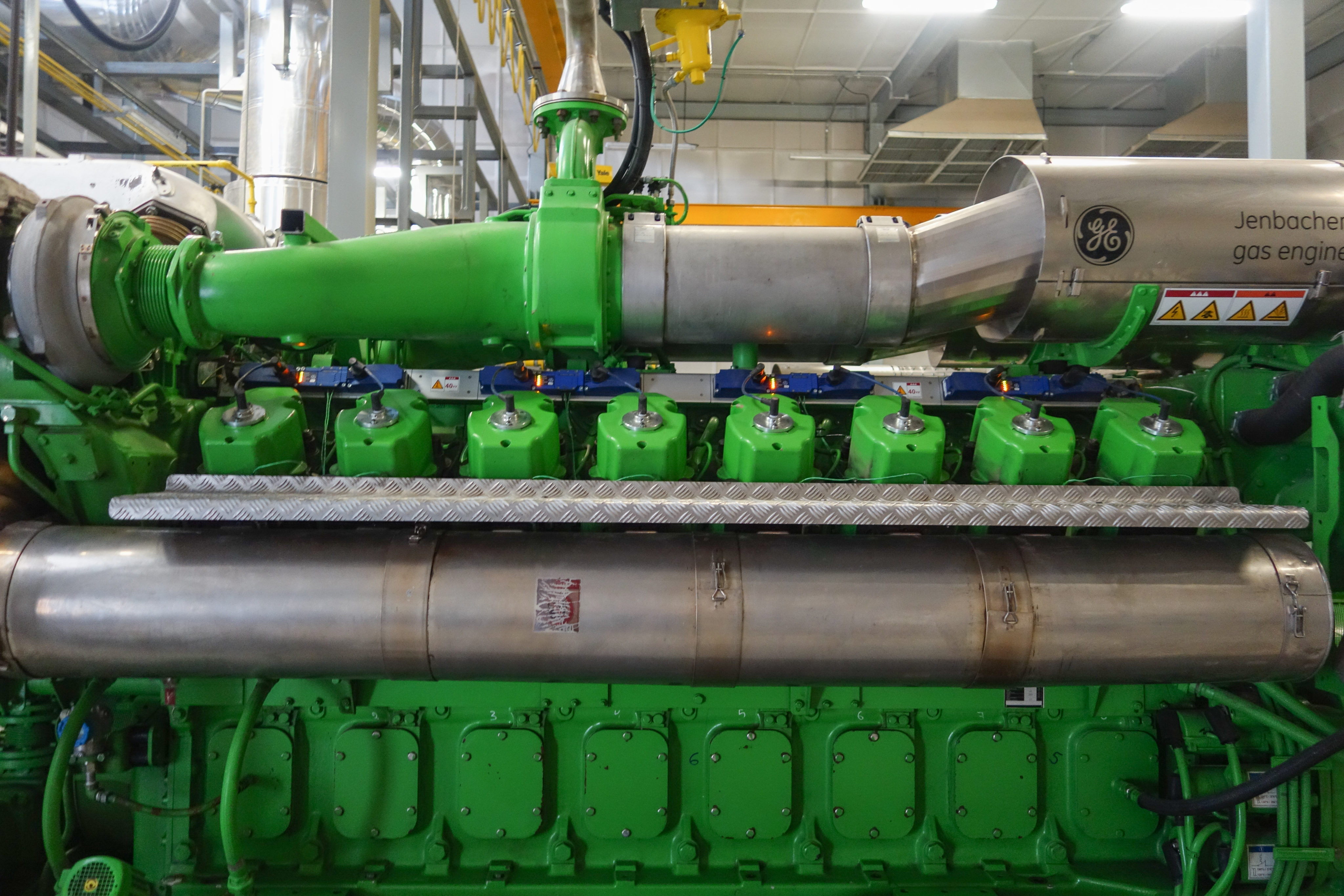

Cone installs a Co-Generation Power Plant at Cone Denim Parras, providing 90% of electrical needs.

Cone launches the first Cone Community fabric collection.

2013

Cone launches Cone 3D, an R&D incubator for technical product innovation, focusing on new technologies. Innovation efforts are focused on the areas of performance, comfort, uniqueness, and sustainability.

2008-2011

Cone Denim debuts its Sustainblue™ line of eco-friendly denim fabrics.

Cone patents S Gene® Yarn Technology, the first of its kind. This new yarn, with dual core technology, is designed to optimize stretch and maximize recovery.

1991

Cone Denim celebrates 100 years!

1969, Mid 1970s

Pinto Wash denim is born after hurricane flooding soaked millions of yards of fabric. To salvage the goods, the fabrics were processed through a solution to randomly remove dye. This resulted in the unique appearance of Cone’s own Pinto Denim. It was picked up by retailers worldwide and became an immediate success.

Cone Denim is the first mill to add skew to fabrics.

1962

Cone Mills is the first producer in the U.S. to manufacture and market stretch denim. The company maintained its leadership in work clothing fabrics but continued to develop this new type of product for the growing casual and sportswear clothing markets.

1940s, 1941

Sustainability becomes a core focus; Cone develops and builds wastewater treatment plants. Later, a federal mandate would require other mills to follow suit.

1941: Half Century

Cone Denim celebrates its first 50 years.

1936

Cone launches Deeptone Denim™, an innovation that quickly gains success in the marketplace due to its durable “leathery” finish, and steadfast promise of stay-fast color and durability

1932

After investigating the new Sanforizer® machines invented by Sanford Cluett, Cone launches Sanforized® denim. Its production reaches 75 million yards per year.

1915, 1921

Levi’s begins buying denim from Cone Mills – the two companies agree to do business with a handshake that has continued for over 100 years.

Cone develops the Indigo Rope Dye Range at its White Oak Plant and receives a patent for the continuous rope indigo dyeing machine

1905

White Oak Cotton Mill starts producing denim, soon to become the largest denim mill in the world. By 1910, White Oak was supplying a third of the world’s denim demand.

1895

Proximity Cotton Mills, the Cone brothers’ first mill, begins weaving denim in close “proximity” to the cotton fields, gins, warehouse, and rail lines.

1891

Brothers Moses and Ceasar Cone establish the Cone Export and Commission Company in New York City.