A CULTURE OF SUSTAINABILITY

Sustainblue™

Changing the way products are made. Changing the way consumers buy goods. Changing our impact on the world. Sustainblue™ is our environmentally friendly start-to-finish approach for making responsible denim. From sourcing raw material, to the processes at our mills, to up-cycling and giving back to the community, Sustainblue™ is Cone Denim's commitment to making a positive impact.

OUR COMMITMENT

2030 Sustainability Goals

Water

We are committed to reducing water usage by 40% by 2030.

Our Flash Finish process is allowing us to save an average of 83% of water compared to traditional denim finishing along with significant chemical reduction.

Energy

We have validated Science Based Targets to reduce our scope 1 and scope 2 GHG emissions 46.2% by 2030 from a 2019 base year. Our Cogeneration system, a combination of heat and power supply, increases our overall energy efficiency and decreases our related environmental impact. Our solar panel initiative in China is helping us reach this goal as well.

Raw Materials

We have partnered with Oritain, which allows us to determine that we are sourcing ethically produced cotton fibers. Combined with our work towards sourcing responsible fibers such as Certified Recycled Cotton, Hemp, Tencel, Ciclo and Repreve, we are making our supply chain more sustainable and have committed to 100% preferred and low climate impact fibers by 2030.

SUSTAINABLE COMPONENTS

Responsibly Sourced Cotton

Oritain™

A groundbreaking technology in cotton traceability; Cone Denim® is the first mill globally to provide documentable cotton transparency, admissible in a court of law.

Our Traceability Initiative

U.S. Cotton Trust Protocol

Brings quantifiable and verifiable goals and measurement to sustainable cotton production and drives continuous improvement in key sustainability metrics.

Recycling pre-consumer fibers and post-consumer goods diverts waste from landfills. The pre-consumer recycled cotton fiber is recovered and reintroduced during our manufacturing process.

Organic Cotton

Our certified Organic Cotton fabrics are made using 100% organically grown cotton without pesticides, herbicides and synthetic fertilizers. Organic cotton grown using methods and materials that have a low impact on the environment.

BCI Cotton

Better Cotton Initiative™ is a global not-for-profit organization for sustainable cotton growing practices from farming, environment and human well-being. It is the largest cotton sustainability program in the world.

Sustainable Fibers

REPREVE®

REPREVE® recycled polyester is one of the fiber components of our Sustainblue™ fabric collection. This recycled material derived from post-consumer waste from plastic bottles is certified and traceable. We are recognized as REPREVE® Champions of Sustainability by Unifi, Inc. celebrating brand and textile partners who have shown exemplary commitment to sustainability.

Lenzing Cellulosic

We incorporate TENCEL™, MODAL, and TENCEL™ x REFIBRA™ blends into our Sustainblue™ fabric collection. These 100% bio-degradable fibers produced from sustainably sourced wood by environmentally responsible processes are desirable for their softness, strength, and inherent moisture absorption.

CiCLO® Technology

Made to last, not here forever. CiCLO® technology helps to reduce microplastic pollution by enabling synthetic fibers that shed from manufacturing and care to biodegrade without compromising durability. CiCLO® fibers are proven to fully biodegrade in seawater, soil, wastewater treatment plant sludge, and landfill conditions.

Lycra® EcoMade

Cone offers LYCRA® Ecomade, a GRS Certified sustainable elastane alternative, as part of our Sustainablue™ collection. Elastane/spandex product that is made with pre-consumer recycled materials. Waste is collected at the company’s manufacturing sites (reducing landfill waste) and blended with virgin fiber.

Roica™

ROICA™ yarn is an alternative to spandex, degrading at a quicker rate in microbiologically active soils. A proprietary polymer that allows the degradation of the spandex without releasing harmful substance under the aerobic condition.

COOLMAX® & THERMOLITE®

COOLMAX® fiber is made from 97% recycled resources such as plastic bottles for a cool dry comfort. THERMOLITE® warming technologies contains up to 35% recycled materials in the fabric content such as plastic bottles with warmth and breathability.

Creora® Regen

A spandex that is made of 100% GRS certified pre-consumer recycled fiber, with a reduction in CO2 emissions by 66.68% when compared to conventional spandex.

Cone Denim Hemp

A hemp denim collection sourced from the US, France or China. We partnered with experts and pioneers that are aligned with our values, quality, expertise, and sustainability.

An Origins Story: From the Ground Up

Sustainable Dyes

Distilled Indigo™

All Cone Denim mills offer our DISTILLED INDIGO™ collection featuring some of the most sustainable indigo dyes available with a dye method recognized by top environmental certification companies. Our collection also includes indigo dyes that are hydrosulfite-free and analine-free.

Natural Indigo

Natural Indigo was the dye-stuff Cone used when we produced our very first fabrics in the late 1800's. Our Natural Indigo is certified USDA Bio Preferred.

TruTone™

Our TruTone™ fabrics are made with a special blend of fiber-dyed Lenzing Modal® and Unifi Repreve® fibers. This unique blend of fibers eliminates the need for overdyeing, reducing overall water usage by 85%. TruTone™ fabrics are currently offered in Future Black, Future Navy and Stay Bright.

COMMUNITY

Cone Community

The Cone® Community Collection of fabrics is designed to support and raise awareness for worthy causes that align with the values and soul of Cone Denim.

Local Impact

From supporting our employees and their families with different programs including health fairs, summer camp and scholarships to giving back to the nearby areas by planting trees, renovating schools, supporting the elderly, disabled and local girl’s orphanage, we are dedicated to making a positive impact on our local communities.

PROCESS

Responsible Manufacturing

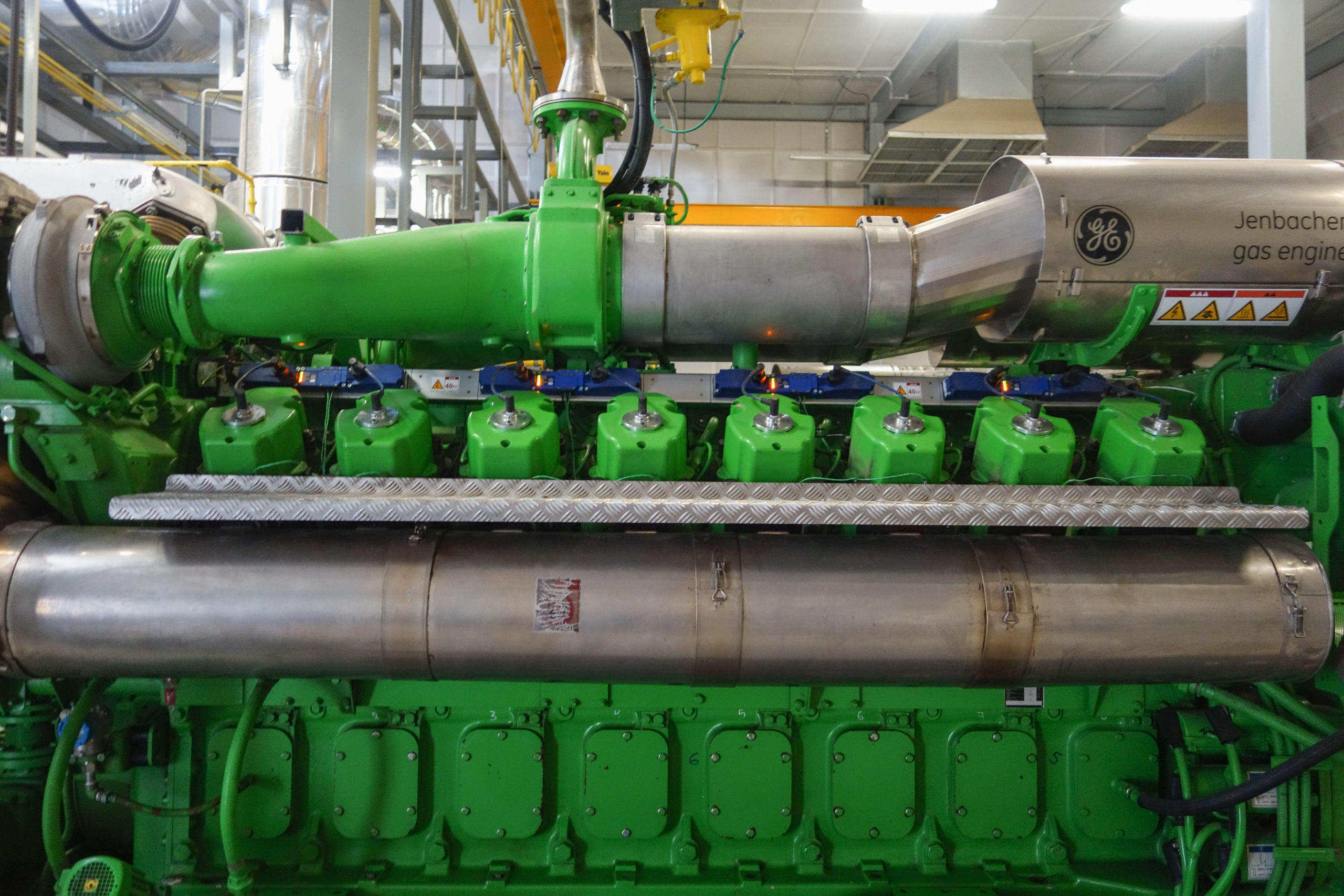

Co-Generation System

In 2015 Cone Denim Parras installed a Cogeneration system to enhance the quality and reliability of the power supply coming to the plant.

-

26%

reduction in greenhouse gas emissions

Using 2016 as the baseline, we have a 26% reduction in Greenhouse gas Emissions associated with the thermal energy capture from the Cogeneration System.

Solar Power

We have installed a rooftop solar panel project at our mill in Jiaxing, China. This project marks our first solar project, and a fourth for our parent company, Elevate Textiles

The solar panel initiative will generate 9 MWH of electricity annually. This new clean energy source will provide a 17% reduction in the plant’s annual GHG emissions.

Ozone Flash Finish

Thanks to our partners at Jeanologia and their G2 Dynamic system, we are now able to conserve on average 85% less water compared to conventional finishing methods.

In addition to significant water savings, this eco-efficient ozone technology uses less energy, fewer chemicals and allows us to engineer fabrics with an affinity for laser and eco garment washing techniques.

PARTNERS & CERTIFICATIONS

It's all about trust

One of the keys to a successful sustainable future is having the right partners–partners as dedicated to responsible practices and innovative ways to improve performance on every level as we are.